Big Bag Discharge

Accessories

Support Frame with Beam

Dec supplies various types of support frames from simple mobile support frames with safety bars to fully integrated frames including beam, hoist and various accessories. The frame will be designed according to the big bag dimensions and weight as well as the local requirements and room layout.

Features

-

Design up to 2 tons

-

Frame in painted steel or stainless steel

-

Beam in galvanized or stainless steel

-

Safety bars

Options

-

Integration of load cells

-

Customized design

-

Tubing in frame

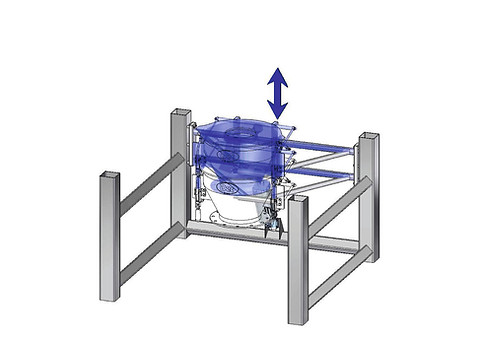

Module Frame

A module frame is suitable for loading with a forklift truck as well as with a chain hoist and can, depending on product characteristics, be equipped with efficient discharge supports. With its compact design, the station can be used as a mobile unit. When using an extendable upper frame achieved by springs or pistons, big bags can be streched during the operation.

Features

-

Design up to 2 tons

-

Frame in painted steel or stainless steel

-

Big bag extension by springs or pneumatic pistons

-

Safety bars

Options

-

Integration of load cells

-

Customized design

-

Tubing in frame

Support Frame for Lifting Column

For the installation in clean rooms where no chain hoist or forklift are allowed for GMP reasons, Dec can provide big bag emptying stations with lifting columns to easily install the big bags on the frame.

To reduce the investment, a single lifting column can be shared between 2 big bag stations.

Features

-

Pneumatic or electrical column

-

Design up to 1 ton

-

Frame in painted steel or stainless steel

-

Safety bars

Options

-

Integration of load cells

-

Customized design

-

Tubing in frame

Lifting Yoke

Dec provides custom made lifting yokes suitable to various sizes of BB and support designs providing the ability of quick and safe connection of the big bag loops for loading by hoist, forklift or lifting column. A clamping device for loose liners can be supplied. Special version available for low height requirements.

Features

-

Design up to 1.9 tons

-

Painted steel or stainless steel

Options

-

Liner holding clamp

-

Low height requirement with counterweight

Hoist

Dec provides pneumatic or electrical hoists as part of a complete station. Pneumatic hoists are mostly used in ATEX areas and electrical hoists for non ATEX environments.

Features

-

Pneumatic or electrical hoist

-

1 ton or 2 ton hoist

-

ATEX 1/21

Options

-

Wireless control

-

Limit switches on rail

-

Hoist with 2 chains for low height requirement

-

Stainless steel chain

-

Customized design

Discharge Stretching Device

The stretching device lowers the connection system and ensures a tight big bag sleeve, thus, the product can be freely discharged.

Pneumatically operated the system is controlled locally by the operator during the big bag docking operation.

The operator lifts the system to connect the big bag and will lower it after in order to stretch the spout.

Features

-

Air operated 6 bars

-

Stroke 300 mm

-

Controlled by local panel

Options

-

Reinforced design for heavy load

Lower Massage

The big bag discharging stations are available with compact, pneumatically operated bottom massaging units, especially suited to deal with poor flowing materials or to break up bridges. In addition, lower massage guarantees operator safety as it prevents the falling of the big bag on the worker in case of a failure of the big bag holder.

Features

-

Pneumatically operated

-

Manual control by local panel

-

GMP design

-

Suitable ATEX 1/21

Options

-

Unit for heavier duty

-

Automated control

Upper Massage

When handling heavily compacted big bags, the station can be supplied with additional side massage either pneumatically or hydraulically driven. The big bag can be de-compacted at different heights before being connected to the docking system. The units can be fitted with brackets for the future installation of the side massaging units.

Features

-

Pneumatically operated

-

Manual control by local panel

-

GMP design

-

Suitable ATEX 1/21

Options

-

Hydraulic unit

-

Preparation for future installation

Breathing Filter with Deflating Function

This arrangement comprises a HEPA filter for the breathing of the system and the prevention of big bag collapsing during the discharge. It is used as much for big bag respiration as for the fluidization of the powder in the transfer line when using a PTS. At the end of the discharge, the filter can be isolated by pressing a push button from a local panel activating BB deflation by the vacuum of the PTS. For hygroscopic or flammable materials the filter can be replaced by nitrogen to guarantee a dry and safe condition.

Features

-

Hepa 12 or 14 filter

-

Deflating function controlled by local panel

-

GMP design

Options

-

Safe change filter

-

Integrated filter

-

CIP

-

Connection to N2

Weight Cells and Dosing Devices

The big bag station frame can be installed on load cells for weight control. Combined with specific dosing valves in the transfer line controlled with the PTS system, you have a fully automated dispensing system directly from the powder discharge station to be emptied.

A typical dosing accuracy of 0.5 -1 kg can be achieved for big bags of one ton. Multiple big bag changes are possible with weight accumulation in case of larger batches.

The load cells are protected from external shocks and include anti-tilting precaution.

Features

-

4 load cells with anti-tilting arrangement

-

Weighing terminal or integration into the main control system

-

Possibility to connect to an MES system

-

Suitable ATEX 1/21

Re-closing Device

Dec has developed its own big bag closing device which allows to reclose the big bag spouts after being opened. The system consist of 2 half plates which are operated by a pneumatic cylinder.

The big bag will be slowly closed during emptying and can be removed from the station after the spout is hermetically closed.

Features

-

Pneumatically operated

-

Controlled by local panel

-

GMP design

-

Suitable zone 1/21

Options

-

Automatic control

-

Preparation of the station for future installation

Combi-Station for Big Bags and Bags

When bags and big bags need to be emptied into the same process, Dec provides a single combined station to execute this task in a dust free manner.

The combined station is usually equipped on one side with a big bag discharging station including a standard double tube docking system and a pneumatically operated bottom massage unit. The other side features the bag emptying station both of which are connected to a common hopper with a single outlet onto which a delumper or fluidization hopper can be installed for lumpy or bridging materials.

The station furthermore includes a ventilation piping system connected to an external extraction system for the venting of the big bags and extraction from the bag station.

Features

-

Standard double tube docking system

-

Ventilation piping and valves

-

Outlet with flange DN 300

-

GMP design

-

Suitable ATEX 1/21

-

Options

-

Extraction system with filter and fan

-

Weighing system